It is estimated that in 100 years, the planet has warmed by 0.9°C [1] . Our generation is already witnessing the consequences of this warming: disappearance of the sea ice in summer, accelerated melting of our glaciers, repeated heatwaves and forest fires, acidification of the oceans, seriously threatened biodiversity [2] … So when I am explains that if we don't change our habits, it is possible that over the next 80 years the planet will warm up by an additional 6.4°C, I don't know about you, but that doesn't leave me indifferent!

What is the carbon footprint of the textile industry?

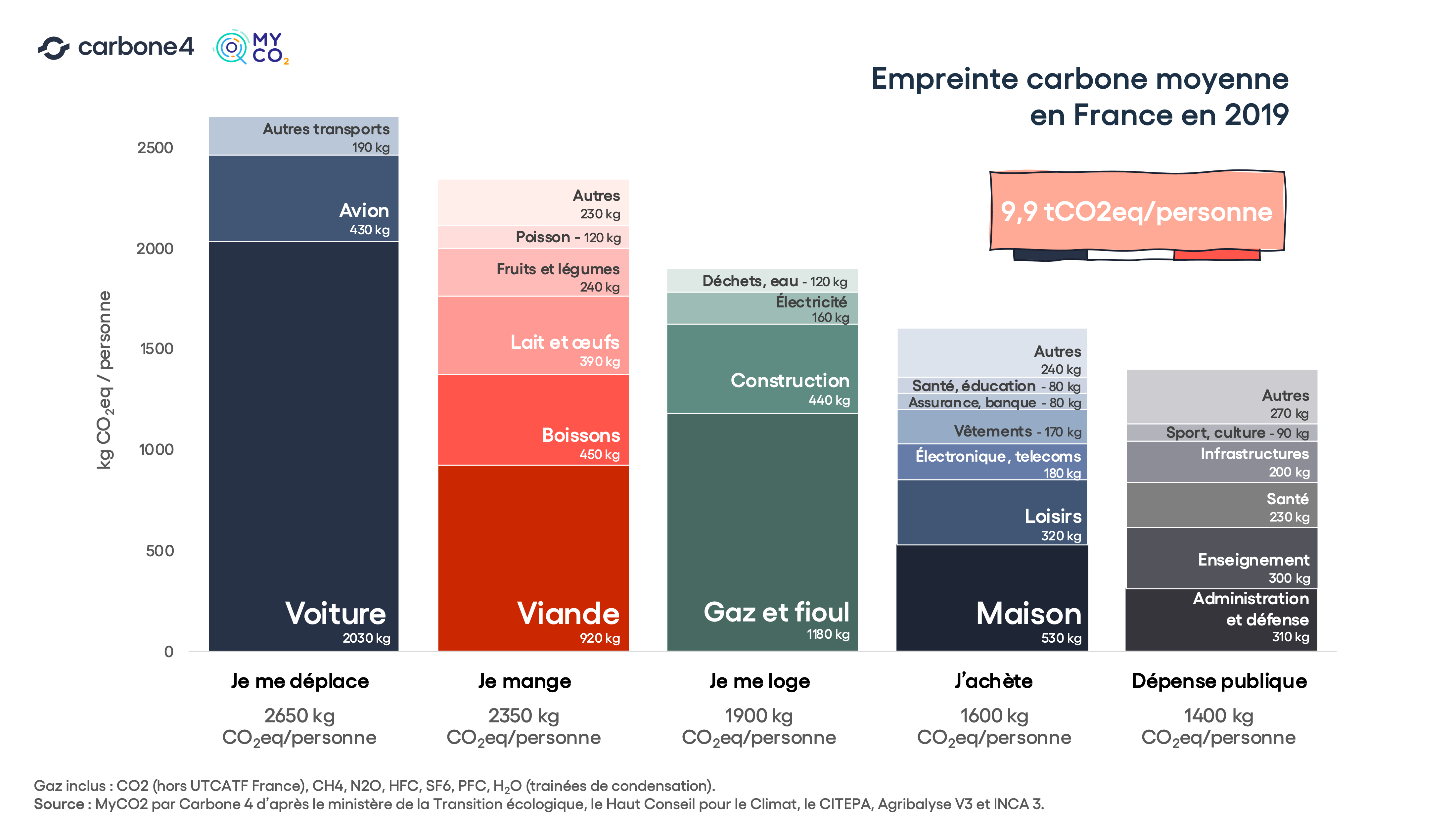

When we take the carbon footprint of a French person [4] , we see that the biggest sources of emissions are food (19.5%), housing (19.2%) and the use of the car (16.3%). Clothing comes a little further behind with 6.3% of emissions. Thus, on a national scale, clothing emits more than the airport industry or the consumption of household appliances.

Obviously, if you are looking to reduce your carbon footprint, a first step would be, for example, to consume more local products, insulate your apartment and travel by bike more often! However, even if we applied these changes to the extreme, I'm sorry to tell you but we would be far from it!

Indeed, with 9.9 tonnes of CO2 emissions per year, the French are still very far from doing what it would take to reach even the threshold of 2°C of additional warming compared to pre-industrial levels. (threshold defined during the Paris agreements [5] ).

To respect this commitment, there is more or less consensus on the fact that our emissions should not exceed 2 tonnes of CO2 per year per inhabitant [6] : Quite a regime!

With 170kg of CO2 per year, clothing would therefore consume 10% of our carbon budget, and this is the challenge of making clothing with a low environmental impact.

Made In where?

When we talk about eco-responsibility in textiles, we are struck by the fact that the entire debate focuses on the place of manufacture.

It is obvious that this will reflect working conditions and deals with the “responsible” aspect of our problem.

But beyond the fact that in our opinion it is normal to produce in “normal” working conditions (this is what Made in the EU guarantees), this is not really where the environmental issues are concentrated.

Indeed, the manufacturing part represents at most 10% of CO2eq emissions, and transport (if it is not done by plane, which is rare), will also represent hardly more than 10%-12% as well.

Yes, from a CO2eq emissions point of view, and pollution in the broad sense, it is the material which concentrates all the environmental issues.

Natural please! Really ??

This is usually the first question we get asked: “are your clothes made from natural fibers?”

Summarizing the debate to this question is unfortunately far too simplistic.

The manufacture of cotton, for example, certainly does not use hydrocarbons as a raw material. But its cultivation requires tractors; its processing of machines; the manufacture of wires too... in short, this industrial process is the source of CO2eq emissions.

To find out what is happening and compare industrial processes with each other, we carry out what is called a Life Cycle Analysis (LCA, or LCA in English).

The ACV as a justice of the peace

Some LCAs available on the internet show that cotton saves around 41% less energy than virgin polyester. However, it paradoxically releases 39% more CO2eq into the atmosphere (uncaptured emissions).

Added to this is the fact that it will take 22,000 liters of water to obtain 1 kg of cotton compared to 17 liters to obtain the same amount of polyester [8] ! A notable difference when we know that the intensification of cotton production in Uzbekistan and Kazakhstan since the 1960s is directly responsible for the drying up of the Aral Sea [9] .

These considerations must ultimately be put into perspective of sustainability and here, the equation clearly tilts in favor of Polyester. Because at equivalent fabric density, Polyester will have a resistance 2 to 10 times greater than cotton, which makes it possible to reduce the carbon footprint per use to a much lower level than what a natural fiber would obtain, particularly if the fabric risks to be subjected to strong constraints as is the case in trail running...

And recycled then?

The debate is more or less of the same nature, and the first preconceived idea that deserves to be killed is that not everything we put in the recycling bin is necessarily recyclable, quite the contrary!

In reality, only a tiny part of the plastic waste we put there is. These are generally plastics numbered 1 (PET), 2 (HDPE) and 5 (PP), a number that can be found on the back of the packaging. Do the exercise of looking behind your yogurt pots and other containers and you will be surprised to see what really deserves to end up in the recycling bin!

The plastic commonly recycled in the textile industry is Polyester (PET). It is obtained by a mechanical process (there are chemical processes) from transparent plastic bottles (most of the time, colored bottles do not enter this process for dyeing reasons (this causes stains on the threads) .

If the use of a recycled raw material saves hydrocarbons, the collection process as well as the various mechanical treatments ultimately increase the carbon footprint of these recycled fibers.

Here too, an LCA carried out on a Newlife yarn manufactured in Italy (probably the European reference in terms of recycled PET yarn) reveals 32% CO2 savings compared to virgin PET manufactured in the same place: this is not enormous, because added to this the common stages of texturing, milling, warping and weaving, the final saving is only 10 to 15% CO2eq compared to a fabric made with virgin PET.

The energy mix above all!

In our eyes, considerations about the place of manufacture of the material and the energy mix used are much more impactful!

Based on IEA figures, we see that CO2eq emissions per energy produced are 71% higher in Italy than in France (5th lowest carbon energy mix in the world).

Conclusion: it is better to choose a good French virgin PET fabric than a recycled Italian, Spanish or Portuguese fabric!

Other pollution factors

Added to this carbon pollution are other pollutions. The dyeing and finishing of textile fibers uses a very large quantity of chemicals. However, not all countries are equal when it comes to the treatment of this waste, and of course, the least conscientious are also the main producers [7] !

In short, the Textile industry isn't always pretty if you're not careful where you step! And it’s especially easy to get lost when it comes to responsible purchasing. To do this, we invite you to take a look at the SloWeAre store, a platform which lists committed and ethical brands and which will help you create a “clean” wardrobe.

[1] https://fr.wikipedia.org/wiki/R%C3%A9chauffement_climatique#cite_note-18

[2] https://www.ecologique-solidaire.gouv.fr/observatoire-national-sur-effects-du-rechauffement-climatique-onerc#e2

[3] https://jancovici.com/climatic-change/gas-a-effect-de-serre-et-cycle-du-carbone/quels-sont-les-gaz-a-agence-de-serre-quels -are-their-contribution-to-the-greenhouse-effect/

[5] https://fr.wikipedia.org/wiki/Accord_de_Paris_sur_le_climat

[6] https://www.lemonde.fr/planete/article/2019/04/11/combien-de-co2-pourrez-vous-emite-dans-votre-vie-si-le-rechauffement-est-contenu -a-1-5-degree_5448606_3244.html

[7] A New Textile Economy: https://www.ellenmacarthurfoundation.org/publications/a-new-textiles-economy-redesigning-fashions-future

[8] https://pdfs.semanticscholar.org/80e3/da631dd6d7d86d288275c390e63849fc4498.pdf

[9] https://fr.wikipedia.org/wiki/Mer_d%27Aral

[10] https://www.amfori.org/resource/countries-risk-classification ;

[11] https://www.francetvinfo.fr/replay-magazine/france-2/cash-investigation/cash-investigation-du-mardi-28-november-2017_2478912.html