What is a 3rd layer or hardshell?

The waterproof jacket is in the 3rd layer or hardshell category. In our case (for trail running 😉), it is a jacket whose aim is to protect from external elements and bad weather such as rain, wind, snow... While having properties adapted to the practice of running foot. Indeed, if we forget this point, we might as well run with a garbage bag or a tarpaulin 🧐

When clothing is waterproof , it limits the penetration of water in liquid form (like rain). We can work on the waterproofness of a fabric by adding a polymer coating (a plastic layer, like yellow oilskins) or by combining this fabric with a technical membrane. This membrane being too fragile to be used in a single layer, it is generally laminated/sandwiched with 1 or 2 layers of another fabric providing other properties: resistance to friction, moisture absorption, etc.

A fabric is said to be breathable when it evacuates the water vapor generated by our body during exercise, in the form of perspiration. The more the fabric allows this moisture to escape, the less it will accumulate. Conversely, if the fabric is not breathable enough, it will retain moisture which will condense and make us wet.

And the homologation for racing in all this?

For mountain races of more than 15km, it is common to find a “waterproof jacket” in the list of mandatory equipment. It is a jacket with a hood and whose seams are waterproofed. In classic sewing, when the needle passes through the material, it creates a tiny hole. To be waterproof, the seam is sealed with tape (iron-on adhesive strip) which seals the perforations.

What is a good waterproof jacket for trail running?

To meet the needs of the trail runner and to protect him as best as possible from external conditions, here are the prerequisites:

- A water-repellent outer material, which allows drops of water to slide off and quickly evacuate from the jacket

- A technical membrane, which allows the passage of humidity generated by the body during activity, in the form of evaporation (from the inside to the outside) and which blocks the passage of water in liquid form (from outside in), like rain

- A construction that limits unnecessary seams while maintaining good mobility (the right balance to find is not always easy). Dividing the jacket into several articulated panels can increase mobility but also increases the risk of getting wet if sewing defects appear over time. Also, more generally: more seams means more areas to seal, therefore more manufacturing time, therefore a higher cost.

- High quality manufacturing, which guarantees top-notch seam sealing

And the Wise jacket in all this?

It all started, as always, with our community. But this time, instead of carrying out the development hidden behind our computer, we organized a workshop on our premises with a small group of passionate trail runners.

Workshop n°1: The sensations and emotions of trail running: what brings us outside, to run and to explore the trails?

The main reasons and criteria that were mentioned during this session were:

- Surpassing yourself (self-confidence, approaching your limits...)

- Freedom (adventure...)

- Introspection (freeing your emotions, refocusing, feeling alive...)

- Nature (evolving in an environment, connecting to your senses...)

- Trail spirit and community (sharing, meetings, etc.)

- The challenge (races, season objectives, training plans, etc.)

Conversely, the idea of maximalism (accumulation of equipment) or crowds (during major races for example) can sometimes be experienced as a consequence that is "experienced" rather than a desired situation.

Workshop n°2: What is your current jacket like?

We went through the different jackets we had to see which details are killer and which ones are stinky.

→ Louise: “My jacket has small pockets, an articulated hood with a sweatband, a simple design and a chest pocket.”

→ Christophe “My jacket has a compacting pocket so I can store it quickly, without it taking up too much space in my bag (or in your sherpa 😉).”

→ Marie: “My jacket has an adjustable hood that follows my movements and protects me even in windy conditions.”

→ Gauthier: “My jacket has a gusset in the back, which opens when I carry my bag under the jacket to protect it and my belongings.”

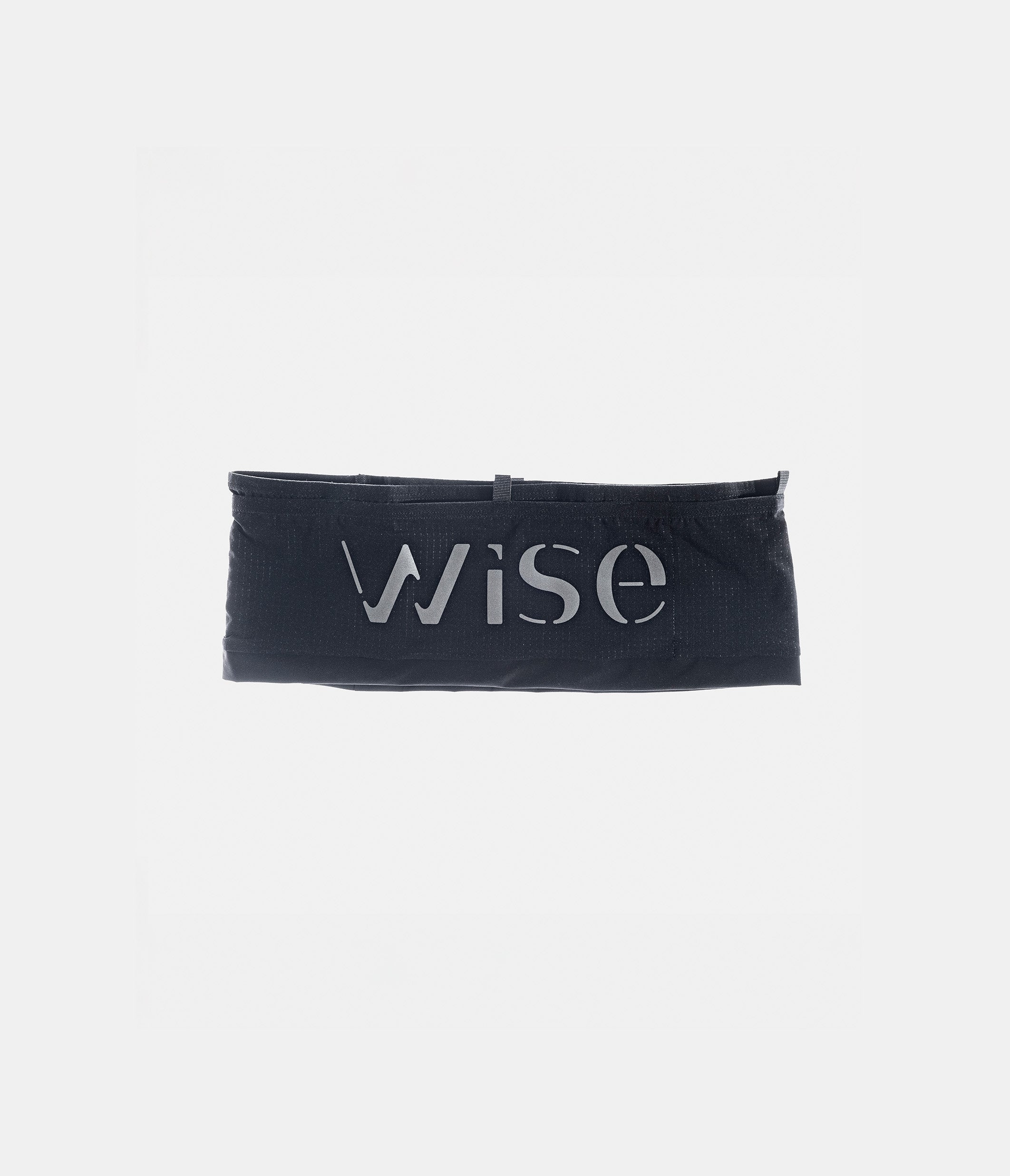

→ Anaïs: “My jacket fits in its belt, which allows you to put it on or take it off quickly. However, the seams are no longer waterproof over time.”

→ Mathieu: “My jacket is colorful and has reflective details so it can be seen in the dark.”

During the discussion, we realized that when the weather was not good, we could tend to feel cold in the extremities and that it is always a struggle to have access to your watch...

In the end, the killer details that we were able to mention are:

- A watch pass

- An integrated mitten to protect from the rain

- A thumb loop

- Reflective elements to ensure good visibility

- An easy to put on zip with an ergonomic puller

- A compaction pocket

- An articulated hood that follows movement and protects even in gusts

- A gusset to carry the bag under the jacket and protect your belongings from the rain

What to learn from these 2 workshops?

The first allowed us to identify the sensory criteria to work on for a positive user experience on trails. The second workshop, more concrete, allowed us to carry out a benchmark (or market study) on the jackets already on the market, to draw advantages and disadvantages.

If we connect what we were able to learn and identify, this is our interpretation:

1/ Clothing, in its physical dimension, mainly influences the criterion of freedom . To not hinder this need and this feeling in any way, it seems important to look at the fit/hang of the jacket (comfortable, rather loose), on the stretch and light material, which does not stick to the skin or gives a plasticky feeling. To feel the least constraint, we also focused on the easy-to-use zip which would allow everyone to make their own combination. A double slider to be able to open only the bottom of the jacket, if you want to access the pockets of your shorts or your belt or to ventilate, for example.

2/ For the criterion of surpassing oneself, one must feel confident . We therefore looked at accessorizing: a protective, articulated hood that does not encroach on our field of vision, as well as a pass-through to ensure that the sleeve does not move and be sure to always be protected.

3/ To challenge themselves, we thought of those who prepare their training carefully and who are ready to brave the elements to do their session. We therefore talked about a watch pass that would allow you to keep an eye on your performance and your objectives.

4/ For nature , our jacket must not contain harmful elements and not have a negative impact. It also seemed important to work on the visibility of the jacket in its environment.

The brief is quite clear. Our hardshell won't be the most minimalist, but it will have thoughtful details.

Searching for solutions:

For this jacket, the most complicated and technical part was the end of the sleeve. Indeed, we must succeed in finding a solution to combine a pass-through, a watch pass and a mitten while remaining as efficient as possible 😅 We must also not lose sight of the objective: the jacket must be waterproof and remain consistent in the choice of solutions and materials.

Let me explain: we could easily add a sort of mitten that would cover the hand, but if the material is not waterproof, the main function is not validated. If you make this extension with the waterproof material, you can reduce comfort and have a piece of the sleeve that “flops and flakes” when you run. If you want to maintain it, you can add an attached part (such as a snap button, a hook-and-loop strip, a magnet, etc.). Not very pleasant, nor very light, nor minimalist. Combining needs, technology, functions while remaining as minimalist as possible, that's the big challenge!

To think and do tests, the simplest thing is sometimes to make paper models (with staples!). Then, to check the behavior of the fabric, I put together a “moke-up” of the piece in question. The goal is not to have a final or usable result, but to see if the concept works as a whole.

Once the technical solutions, the design have been refined and the technical file has been drawn up, it’s time for the model makers to work. At this stage, the first design phase is finished. We can therefore send all the documents and the pattern to our workshop for prototyping.

The first prototype: the first draft.

In the best case scenario, this first prototype is functional. However, it is very often necessary to rework the volume so that the fit of the garment aligns with our silhouette and the finishes are consistent with our positioning.

This time, we had the chance to discover the prototype directly at Petratex and to be able to debrief together on the issues related to manufacturing and prototyping. We were able to test our fabric as well as the strength of the seams in their laboratory.

Back in Annecy, it's time for fitting and field testing sessions with several people. Here is what we noticed:

- The compaction pocket is not functional.

- Some seams are superfluous and can be optimized.

- The shape of the sleeve is not conclusive → modification and improvement of the concept.

- Optimization of patterning and material consumption by modifying the shape of certain parts.

- Aesthetic details and finishes can be refined.

- Accessories (zip and elastic etc.) are replaced by other more suitable ones.

- The overall volume is adjusted to have a comfortable but not too loose jacket.

- The hood is optimized to suit a range of different head sizes.

- The back gusset is modified to accommodate a standard trail vest.

- The tape used to seal the seams is not waterproof enough.

And here we go again for updating the drawings, the technical file and the patterning to get back to prototyping.

The second prototype

At this stage, we have a jacket that really starts to look like a real jacket! This time we were able to make 2 prototypes in 2 different sizes to be able to test them thoroughly using several trail runner profiles.

Workshop n°3: Fitting and field testing of the jacket with our small group of enthusiasts

- The gusset doesn't look very nice when you're not carrying a bag.

- It still lacks volume in the chest to be comfortable and run with your trail vest underneath.

- The watch strap is not oriented correctly and it is difficult to view the screen.

- The visor is too flexible, you need to add a piece to stiffen it. This piece will allow water to run off the sides and not directly onto the face.

- The pocket for folding the jacket is not optimized: when the jacket is stored, it is not compacted enough.

All this gave us material to think about areas for improvement for the next prototype.

The third prototype and “size set”: ready to drop 😎

And There you go ! Our jacket is complete at this point!

We'll let you see what's going on here 😉